We understand what our customers wish ... ...we know the correct answer! |

MODULAR System: - Offers component extensions according to the requirements (e.g. charging from two sides, etc.)

- The fixed interior cleaning system provides for optimum microbiological conditions

- Product reclamation

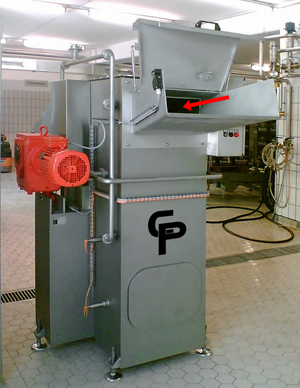

Manual Charging: Type DP | | Automatic charging: Type CP

— for industrial use —

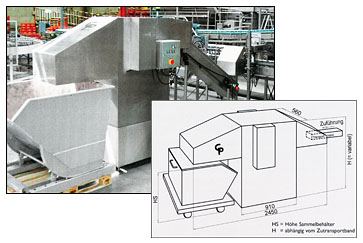

CONTI-Press (CP)

Due to its compact design (only a small space required) it fits in every bottling company, where misfilled cans are guided/pushed out of the process.

Cans with incorrect filling heights are emptied at the place of origin by squeezing. At the same time they are flattened and transported to the collecting bin. |

| Can presses to becharged manually are the first-choice solution for canteen kitchens,

staff restaurants etc.

|

|

In this connection, ergonomics are important.

Easy to operate, low charging height |

- Minimum space required (about 1 sq.m.)

- Immediate operational conditions

|

Typ: CP | | Charging: | Bulk conveyor | | - Charging conveyor

- Belt conveyor

- Large containers (pallet cages)

- Pushers or others

| Typ: DP | | Charging: | manually | | - Individually

- Whole packing units

- Whole boxes

| | | Design features:

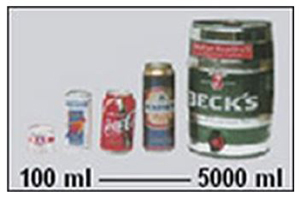

• Pressing full and empty cans

• Product relamation

• For container sizes: 100 ml – 5000 ml

• Microbiologically safe

as cleaning system fixed in the interior

• Parts in contact with the product: stainless steel

• Solid industrial execution

• Principle of rotation (no oil-based hydraulics) |

Also suitable for cans with

carbonator

| | |

Typ | Capacity

cans/h (approx)

(up to 500ml) | DP 400 | 250 | DP 600 | 1000-1500 | CP 600

KP 900

| ?? 6000

Cans/buckets

of 10 litres

about 120 cans/h | | |

|

Type: DP 600 Can presses Euro pat.

with product reclamation

For full cans, in special cases (product reclamation)

the HEIN can press is extended by the required components in such a form that the reclaimed product is transported to processing in a controlled manner.

A fixed interior flushing provides for microbiologically safe conditions. - Preliminary filter

- Cartridge filter

- Product pump

- Level control

- Product collecting trough

- Bypass system (emptying/cleaning)

- Interior cleaning system

| |

|

|

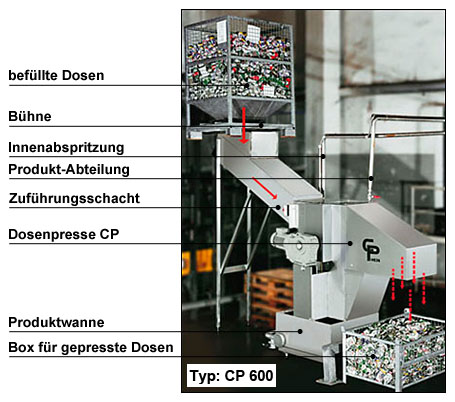

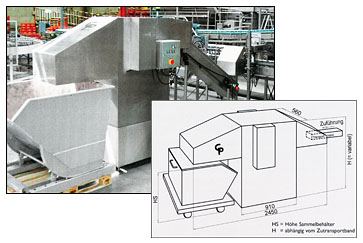

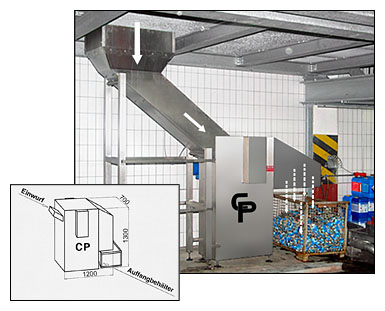

And now some examples of use Type: CP

Charging:

Bulk conveyor

The CP can press

– here in the cellar of a brewery – is charged with whole cage pallets.

The forklift truck drops the cage pallet on a platform (with centering frame).

After opening a slide in the bottom of the pallet, the flow of cans is continuously charged to the CP via a duct.

Time of emptying per cage pallet: about 20 min.

The drained product runs into a collecting trough where it is pumped off, regulated by a level control.

A fixed interior flushing provides for microbiologically safe conditions.

| |

|

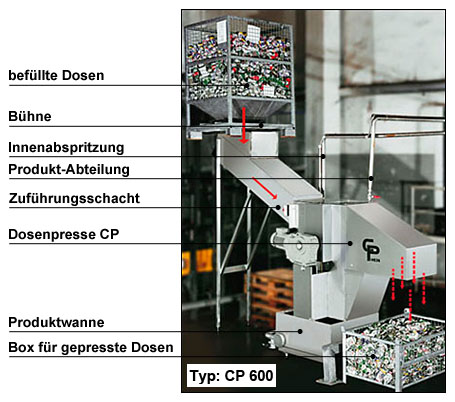

Type: CP 600 |

For this system, charging is made through the ceiling of the cellar into the collecting funnel placed beneath.

Charging: in whole containers

The staff working in the cellars must only ensure that the cage pallet contained the flattened cans is not overfilled. | | The disposal is made centrally from different areas of the system (filled cans und empty cans).

Charging is made by a conveyor. |

|

|

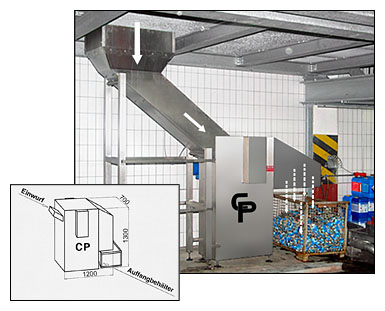

Type: CP 600 Charging by belt conveyor |

Place of installation: charger outlet/ filling height control

Charging: from the pusher on a belt conveyor

...to the can press | | |

|

|

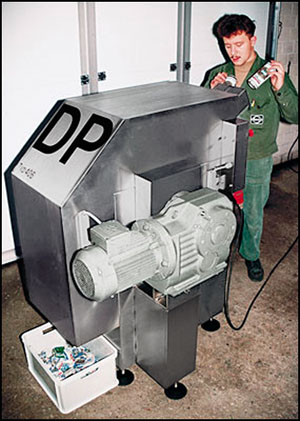

Examples of use for Type: DP 400

| |  Type: DP 400 |

|

manually

• individually

• in whole packing units

• in whole boxes

• or otherwise

Can presses to be charged manually are the first-choice solution for users in other areas as well (e.g. canteen kitchens, staff restaurants)

Ergonomics are important:

• easy to operate

• low charging height |

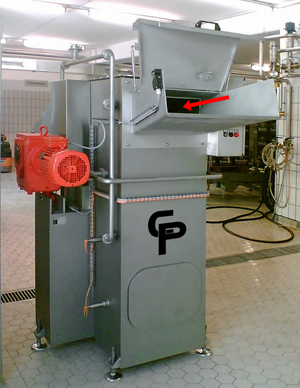

Type: CP 600 | |

Type: CP 600 |

Can presses

- here in the cellar of a brewery

- Intended use: for filled

5000 ml cans with carbonator

- microbiologically safe,

as cleaning system fixed in the interior |

Charging:

• in whole boxes

• in whole packing units |

manually

|

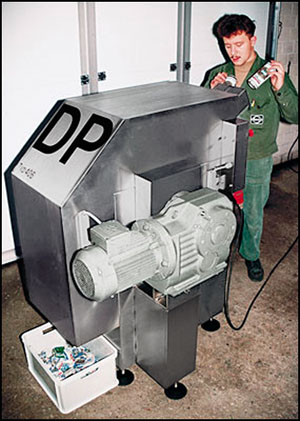

Type: DP 600 |

manual charging:

Type: DP 600 Can press (Type DP 600) for manual charging.

Intended use: for filled 500 ml and 5000 ml cans

| |

TYPE: KP 900 Can press for cans of 10 litres

Capacity: up to 120 cans/h |

|